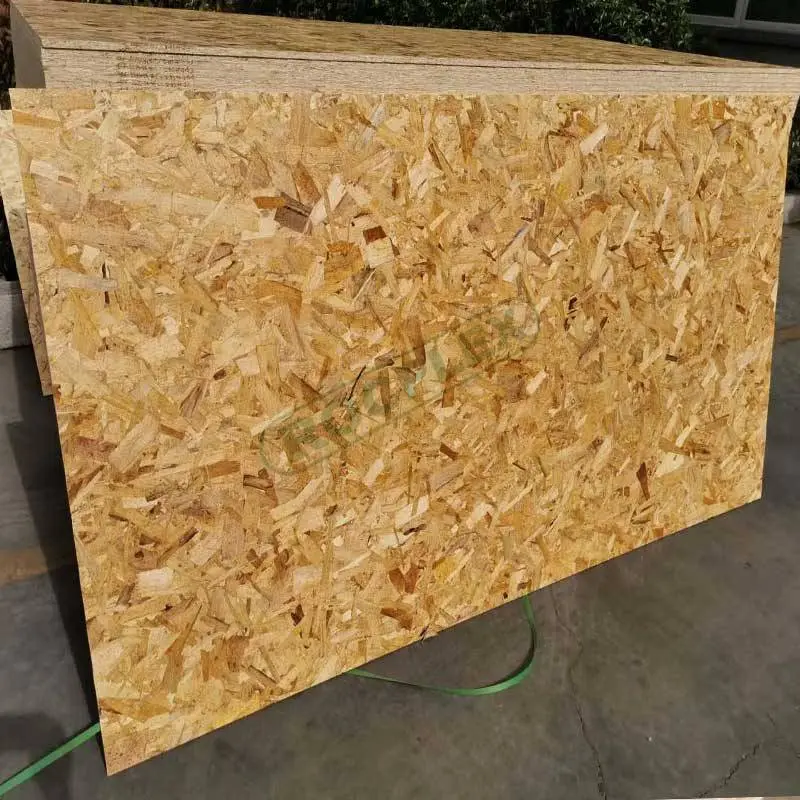

OSB Oriented Strand Board

Oriented Strand Board (OSB): A Comprehensive Guide

Oriented Strand Board (OSB) is a widely used engineered wood product known for its versatility, durability, and cost-effectiveness. Its applications range from construction and flooring to furniture and packaging, making it a staple material in numerous industries.

OSB is made by compressing layers of wood strands or flakes with adhesives under high heat and pressure. These strands are arranged in specific orientations to enhance the board’s structural integrity and strength, giving OSB its unique characteristics.

The Manufacturing Process of OSB

-

Raw Material Selection

-

OSB is primarily made from fast-growing, low-diameter trees such as aspen, southern yellow pine, and poplar. These species are chosen for their availability and workability.

-

Debarking and Flaking

-

Drying

-

Adhesive Application

-

Layer Formation

-

Compression and Curing

-

Trimming and Finishing

Advantages of OSB

-

Strength and Durability

-

Cost-Effectiveness

-

Sustainability

-

Versatility

-

Moisture Resistance

Applications of OSB

-

Construction

-

Flooring

-

It serves as a subfloor material, providing a smooth and stable base for carpets, tiles, and hardwood flooring.

-

Roof Decking

-

Furniture

-

Packaging

OSB vs. Plywood

-

Strength

-

Cost

-

Moisture Resistance

-

Workability

Types of OSB

-

Standard OSB

-

Moisture-Resistant OSB

-

Structural OSB

-

Fire-Retardant OSB

Environmental Impact of OSB

-

Sustainable Forestry

-

Low Waste

-

Recyclability

Common Issues and Solutions

-

Moisture Swelling

-

Edge Damage

-

Delamination

Maintenance and Care

-

Sealing

-

Cleaning

-

Inspection

Frequently Asked Questions

1. What is OSB made of?

OSB is made from wood strands or flakes, bonded together with adhesives and compressed under heat and pressure.

2. How is OSB different from plywood?

OSB is composed of wood strands arranged in specific orientations, while plywood is made from thin layers of wood veneer glued together.

3. Is OSB waterproof?

Standard OSB is not fully waterproof, but moisture-resistant varieties are available for use in humid conditions.

4. Can OSB be painted?

Yes, OSB can be painted. Proper surface preparation, including sanding and priming, is essential for a smooth finish.

5. Is OSB environmentally friendly?

Yes, OSB is eco-friendly due to its use of fast-growing trees, efficient manufacturing processes, and recyclability.

6. What are the standard sizes of OSB panels?

Common sizes include 4×8 feet panels with thicknesses ranging from 6 mm to 25 mm.

7. How should OSB be stored?

Store OSB panels in a dry, flat area to prevent warping and moisture absorption.

8. Can OSB be used outdoors?

Yes, moisture-resistant OSB can be used outdoors, but additional sealing is recommended for prolonged exposure to the elements.

9. How does OSB perform under heavy loads?

OSB’s cross-oriented layers provide excellent load-bearing capacity, making it suitable for structural applications.

10. Is OSB flammable?

Untreated OSB is flammable, but fire-retardant OSB panels are available for enhanced safety.

11. Can OSB be recycled?

Yes, OSB can often be recycled into new wood products or used as biomass fuel.

12. How does OSB impact indoor air quality?

Modern OSB panels use low-emission adhesives, minimizing the release of volatile organic compounds (VOCs).

13. What tools are needed to cut OSB?

Standard woodworking tools such as circular saws or jigsaws can be used to cut OSB.

14. Can OSB be used for soundproofing?

While not specifically designed for soundproofing, OSB can reduce sound transmission when used with other insulating materials.

15. How long does OSB last?

With proper installation and maintenance, OSB can last for decades, even in demanding applications.