The Ultimate Guide to OSB4: Everything You Need to Know

Oriented Strand Board (OSB) is a versatile and widely used building material that has gained popularity over the years. Among its various grades, OSB4 stands out as a particularly robust and durable option. In this comprehensive guide, we will delve into everything you need to know about OSB4, including its properties, applications, benefits, and much more. Whether you’re a DIY enthusiast or a professional builder, this article will provide you with valuable insights into this remarkable material.

What is OSB4?

Understanding OSB

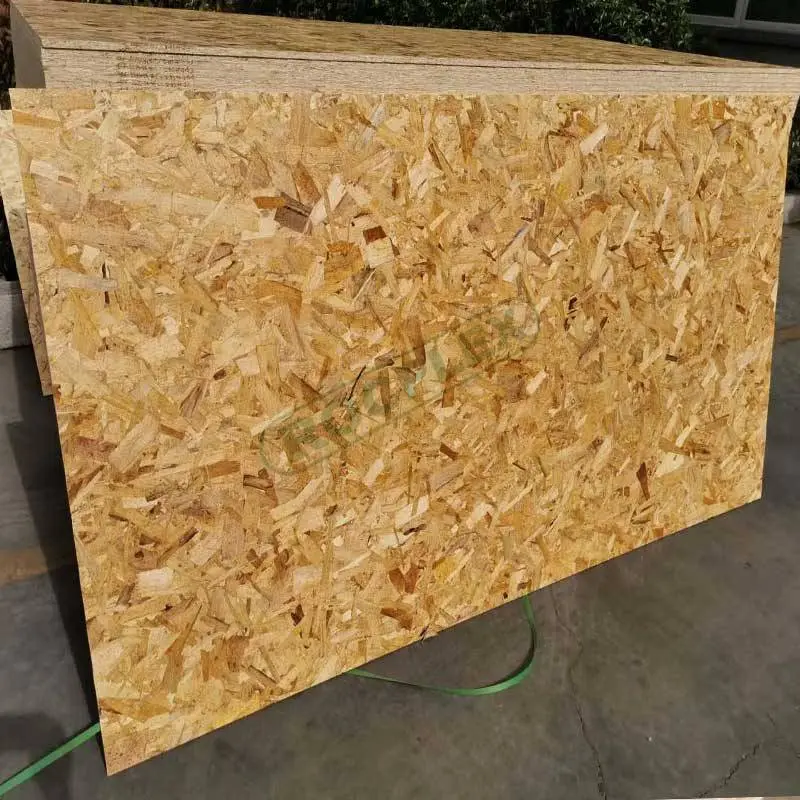

Oriented Strand Board (OSB) is an engineered wood product that is made by compressing layers of wood strands with adhesives. These strands are oriented in specific directions to enhance the board’s strength and stability. OSB is commonly used in construction for sheathing, flooring, and roofing.

OSB4: The Heavy-Duty Option

OSB4 is a specific grade of OSB that is designed for heavy-duty applications. It is manufactured to meet stringent standards, ensuring superior performance in demanding environments. OSB4 is characterized by its high load-bearing capacity, moisture resistance, and durability, making it suitable for both structural and non-structural uses.

Properties of OSB4

Strength and Durability

One of the most notable properties of OSB4 is its exceptional strength. The oriented strands and high-quality adhesives used in its manufacture contribute to its ability to withstand heavy loads and resist deformation. This makes OSB4 an excellent choice for structural applications such as flooring and roofing.

Moisture Resistance

OSB4 is engineered to resist moisture, making it suitable for use in environments where exposure to water is a concern. While it is not entirely waterproof, its moisture-resistant properties ensure that it maintains its structural integrity even in damp conditions.

Dimensional Stability

OSB4 exhibits excellent dimensional stability, meaning it is less likely to expand or contract with changes in temperature and humidity. This property is crucial for maintaining the integrity of structures over time.

Eco-Friendliness

OSB4 is made from fast-growing, sustainable wood species, making it an environmentally friendly choice. Additionally, the manufacturing process minimizes waste, further enhancing its eco-credentials.

Applications of OSB4

Structural Sheathing

OSB4 is commonly used as structural sheathing in walls, roofs, and floors. Its high load-bearing capacity and dimensional stability make it an ideal choice for these applications.

Flooring

OSB4 is often used as subflooring in residential and commercial buildings. Its strength and durability ensure that it can support heavy loads and resist wear and tear over time.

Roofing

In roofing applications, OSB4 provides a stable and durable base for roofing materials. Its moisture resistance is particularly beneficial in this context, as it helps to prevent damage from exposure to the elements.

Furniture and Cabinetry

OSB4 is also used in the manufacture of furniture and cabinetry. Its strength and aesthetic appeal make it a popular choice for creating sturdy and attractive pieces.

Packaging

Due to its durability and cost-effectiveness, OSB4 is sometimes used in packaging applications, particularly for heavy or bulky items.

Benefits of Using OSB4

Cost-Effectiveness

OSB4 is generally more affordable than other engineered wood products, such as plywood. This cost-effectiveness makes it an attractive option for budget-conscious builders and DIY enthusiasts.

Ease of Installation

OSB4 is easy to cut, shape, and install, making it a convenient choice for a variety of projects. Its uniform composition ensures consistent performance and ease of handling.

Sustainability

As mentioned earlier, OSB4 is made from sustainable wood sources and manufactured with minimal waste. This makes it an environmentally responsible choice for those looking to reduce their ecological footprint.

Versatility

The wide range of applications for OSB4 highlights its versatility. Whether you’re working on a structural project or creating custom furniture, OSB4 can meet your needs.

Comparing OSB4 to Other OSB Grades

OSB1

OSB1 is a general-purpose grade of OSB that is suitable for non-structural applications. It is less durable and moisture-resistant than OSB4, making it unsuitable for heavy-duty or outdoor use.

OSB2

OSB2 is a slightly more robust grade than OSB1, but it still falls short of the performance characteristics of OSB4. It is typically used in dry conditions and for light structural applications.

OSB3

OSB3 is a popular choice for structural applications in dry and humid conditions. While it offers good moisture resistance, it is not as durable as OSB4 and may not be suitable for the most demanding environments.

OSB4

As discussed, OSB4 is the most durable and moisture-resistant grade of OSB. It is designed for heavy-duty applications and can withstand harsh conditions, making it the top choice for structural and outdoor use.

Installation Tips for OSB4

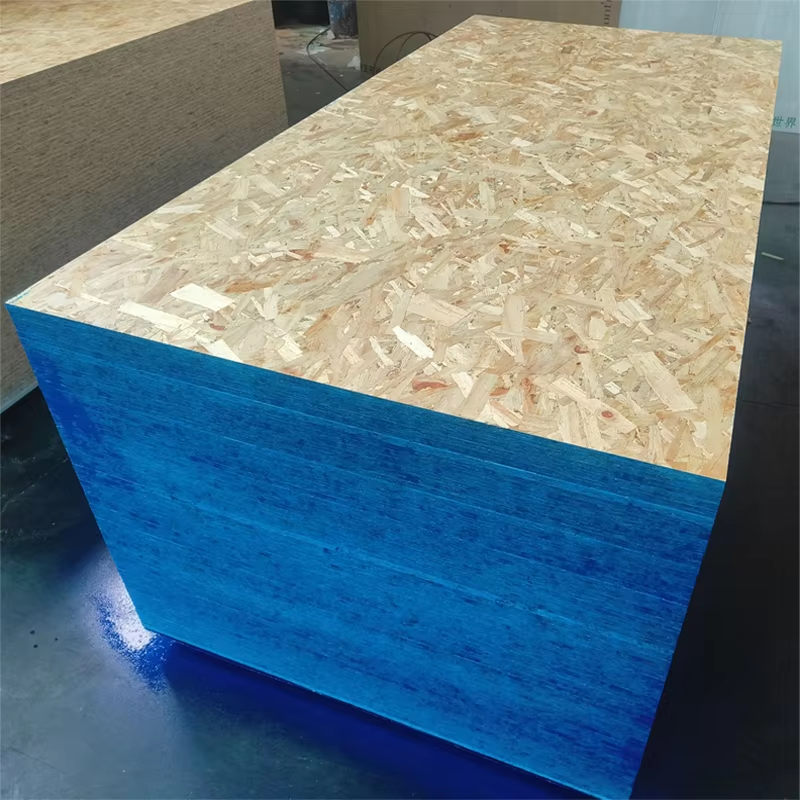

Proper Handling and Storage

To ensure the best performance from OSB4, it is important to handle and store it correctly. Keep the boards flat and supported to prevent warping, and store them in a dry, covered area to protect them from moisture.

Cutting and Shaping

OSB4 can be easily cut and shaped using standard woodworking tools. Use a circular saw or table saw for straight cuts, and a jigsaw for curved or intricate shapes. Always wear appropriate safety gear, such as goggles and gloves, when cutting OSB4.

Fastening

When fastening OSB4, use screws or nails that are appropriate for the thickness of the board. For structural applications, follow the manufacturer’s recommendations for fastener spacing and type to ensure a secure and stable installation.

Sealing and Finishing

While OSB4 is moisture-resistant, it is still a good idea to seal the edges and surfaces with a suitable sealant or paint, especially if it will be exposed to the elements. This will further enhance its durability and longevity.

Maintenance and Care for OSB4

Regular Inspections

To ensure the longevity of OSB4, conduct regular inspections to check for signs of damage or wear. Look for any cracks, splits, or areas where moisture may have penetrated.

Cleaning

Keep OSB4 clean by removing any dirt or debris that may accumulate on its surface. Use a mild detergent and water for cleaning, and avoid using harsh chemicals that could damage the board.

Repairs

If you notice any damage to OSB4, such as cracks or splits, repair it promptly to prevent further deterioration. Use wood filler or epoxy to fill in any gaps, and sand the area smooth before applying a sealant or paint.

Protecting Against Moisture

While OSB4 is moisture-resistant, it is still important to protect it from prolonged exposure to water. Ensure that any OSB4 used in outdoor applications is properly sealed and finished, and consider using a waterproof membrane in areas where it will be exposed to standing water.

Environmental Impact of OSB4

Sustainable Sourcing

OSB4 is made from fast-growing, sustainable wood species, such as aspen and poplar. These trees are harvested from managed forests, ensuring a continuous supply of raw materials without depleting natural resources.

Manufacturing Process

The manufacturing process for OSB4 is designed to minimize waste and energy consumption. Wood strands are carefully selected and oriented to maximize the strength and stability of the final product, and any offcuts or waste materials are recycled or repurposed.

End-of-Life Disposal

At the end of its life, OSB4 can be recycled or repurposed, reducing its environmental impact. Some manufacturers also offer take-back programs, where old OSB4 boards are collected and recycled into new products.

Frequently Asked Questions (FAQs)

What is the difference between OSB4 and plywood?

OSB4 and plywood are both engineered wood products, but they differ in their composition and performance characteristics. OSB4 is made from compressed wood strands, while plywood is made from thin layers of wood veneer. OSB4 is generally more cost-effective and has better moisture resistance, while plywood offers a smoother surface and is easier to finish.

Can OSB4 be used outdoors?

Yes, OSB4 can be used outdoors, but it should be properly sealed and finished to protect it from prolonged exposure to moisture. While OSB4 is moisture-resistant, it is not entirely waterproof, so additional protection may be necessary in areas with heavy rainfall or standing water.

How does OSB4 compare to other OSB grades?

OSB4 is the most durable and moisture-resistant grade of OSB, making it suitable for heavy-duty and outdoor applications. Other grades, such as OSB1 and OSB2, are less durable and are typically used for non-structural or light structural applications.

Is OSB4 environmentally friendly?

Yes, OSB4 is considered environmentally friendly due to its sustainable sourcing and manufacturing process. It is made from fast-growing, renewable wood species, and the manufacturing process minimizes waste and energy consumption.

Can OSB4 be painted or stained?

Yes, OSB4 can be painted or stained, but it is important to properly prepare the surface first. Sand the surface to remove any rough spots, and apply a primer before painting or staining to ensure an even finish.

How long does OSB4 last?

The lifespan of OSB4 depends on its application and how well it is maintained. When used in structural applications and properly maintained, OSB4 can last for several decades. In outdoor applications, its lifespan may be shorter if it is not adequately protected from moisture.

Is OSB4 suitable for flooring?

Yes, OSB4 is commonly used as subflooring in residential and commercial buildings. Its strength and durability make it an excellent choice for supporting heavy loads and resisting wear and tear.

Can OSB4 be used for roofing?

Yes, OSB4 is often used in roofing applications as a stable and durable base for roofing materials. Its moisture resistance is particularly beneficial in this context, as it helps to prevent damage from exposure to the elements.

How do I cut OSB4?

OSB4 can be easily cut using standard woodworking tools, such as a circular saw or table saw for straight cuts, and a jigsaw for curved or intricate shapes. Always wear appropriate safety gear, such as goggles and gloves, when cutting OSB4.

What is the cost of OSB4?

The cost of OSB4 varies depending on the manufacturer, supplier, and region. Generally, OSB4 is more affordable than other engineered wood products, such as plywood, making it a cost-effective choice for many construction projects.

Conclusion

OSB4 is a versatile, durable, and cost-effective building material that is suitable for a wide range of applications. Its strength, moisture resistance, and dimensional stability make it an excellent choice for structural and outdoor use, while its eco-friendly properties make it a responsible choice for environmentally conscious builders. Whether you’re working on a construction project, creating custom furniture, or packaging heavy items, OSB4 is a reliable and sustainable option that can meet your needs.

By understanding the properties, applications, and benefits of OSB4, you can make informed decisions about its use in your projects. With proper installation, maintenance, and care, OSB4 can provide long-lasting performance and contribute to the success of your endeavors.