Laminated OSB: The Ultimate Guide to Oriented Strand Board

Laminated Oriented Strand Board (OSB) is a versatile and cost-effective building material that has gained popularity in the construction industry. Known for its strength, durability, and affordability, laminated OSB is used in a wide range of applications, from sheathing and flooring to roofing and wall panels. This comprehensive guide will explore everything you need to know about laminated OSB, including its benefits, applications, installation tips, and frequently asked questions.

Table of Contents

- What is Laminated OSB?

- History of OSB

- Manufacturing Process of Laminated OSB

- Types of Laminated OSB

- Benefits of Laminated OSB

- Applications of Laminated OSB

- Installation Tips for Laminated OSB

- Maintenance and Care

- Environmental Impact of Laminated OSB

- FAQs About Laminated OSB

- Conclusion

1. What is Laminated OSB?

Laminated OSB is a type of engineered wood product made by compressing and bonding strands of wood with adhesive. The strands are oriented in specific directions to enhance the board’s strength and stability. The lamination process involves applying a protective layer to the surface of the OSB, which improves its resistance to moisture, wear, and tear.

2. History of OSB

OSB was first developed in the late 1970s as an alternative to plywood. The need for a more cost-effective and sustainable building material led to the creation of OSB, which quickly gained traction in the construction industry. Over the years, advancements in technology and manufacturing processes have improved the quality and performance of OSB, making it a preferred choice for many builders and contractors.

3. Manufacturing Process of Laminated OSB

The manufacturing process of laminated OSB involves several steps:

- Strand Preparation: Wood strands are cut from logs and dried to the appropriate moisture content.

- Blending: The strands are mixed with adhesive resins and wax to enhance bonding and moisture resistance.

- Mat Formation: The blended strands are arranged in layers, with each layer oriented perpendicular to the previous one to increase strength.

- Pressing: The mat is compressed under high pressure and temperature to form a solid board.

- Lamination: A protective layer is applied to the surface of the OSB to improve its durability and resistance to environmental factors.

- Cutting and Finishing: The OSB is cut to size and finished according to the desired specifications.

4. Types of Laminated OSB

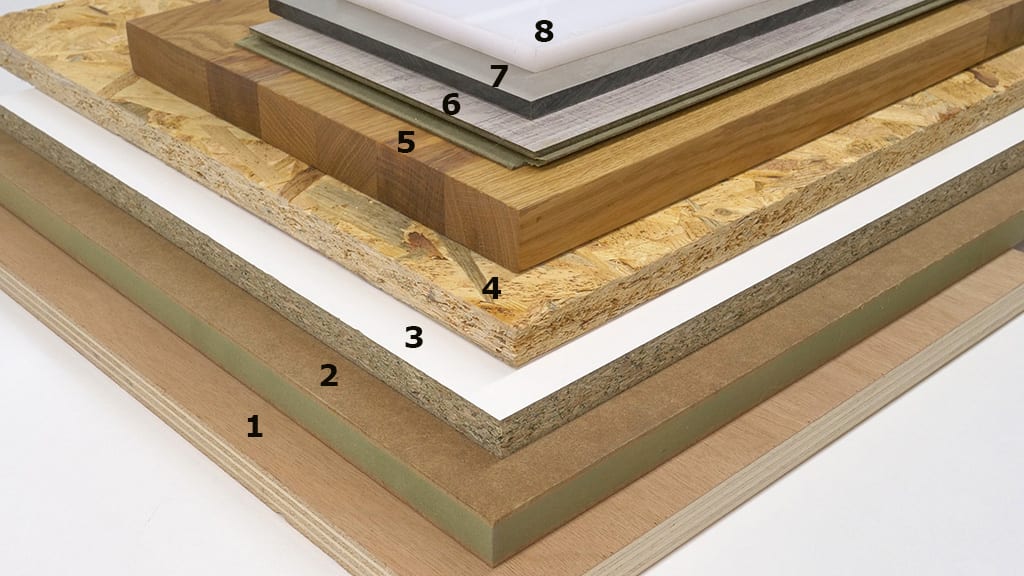

There are several types of laminated OSB available, each designed for specific applications:

- Standard Laminated OSB: Suitable for general construction purposes, such as sheathing and subflooring.

- Moisture-Resistant Laminated OSB: Designed for use in areas with high humidity or moisture, such as bathrooms and kitchens.

- Fire-Retardant Laminated OSB: Treated with fire-retardant chemicals to enhance its resistance to fire.

- Structural Laminated OSB: Engineered for load-bearing applications, such as roof and floor systems.

Caption: Different types of laminated OSB are available for various construction needs.

5. Benefits of Laminated OSB

Laminated OSB offers numerous benefits, making it a popular choice among builders and homeowners:

- Cost-Effective: Laminated OSB is more affordable than plywood and other building materials.

- Strength and Durability: The oriented strands and lamination process enhance the board’s strength and resistance to wear and tear.

- Moisture Resistance: The protective layer on laminated OSB improves its resistance to moisture, making it suitable for use in humid environments.

- Ease of Installation: Laminated OSB is lightweight and easy to cut, making it simple to install.

- Sustainability: OSB is made from fast-growing, renewable wood species, making it an environmentally friendly option.

6. Applications of Laminated OSB

Laminated OSB is used in a wide range of construction applications, including:

- Sheathing: Laminated OSB is commonly used as sheathing for walls, roofs, and floors.

- Subflooring: It provides a stable and durable base for flooring materials.

- Roof Decking: Laminated OSB is used as roof decking to support roofing materials.

- Wall Panels: It is used in the construction of wall panels for both interior and exterior applications.

- Furniture: Laminated OSB is also used in the manufacture of furniture, such as cabinets and shelves.

7. Installation Tips for Laminated OSB

Proper installation is crucial to ensure the performance and longevity of laminated OSB. Here are some tips to follow:

- Acclimate the OSB: Allow the OSB to acclimate to the environment where it will be installed for at least 48 hours.

- Use the Right Fasteners: Use corrosion-resistant nails or screws to secure the OSB.

- Leave Expansion Gaps: Leave a 1/8-inch gap between panels to allow for expansion and contraction.

- Seal the Edges: Seal the edges of the OSB with a waterproof sealant to prevent moisture penetration.

- Follow Manufacturer Guidelines: Always follow the manufacturer’s installation guidelines for best results.

8. Maintenance and Care

Laminated OSB requires minimal maintenance, but proper care can extend its lifespan:

- Regular Inspections: Inspect the OSB regularly for signs of damage or wear.

- Clean the Surface: Clean the surface of the OSB with a mild detergent and water to remove dirt and debris.

- Repair Damage Promptly: Repair any damage, such as cracks or splits, promptly to prevent further deterioration.

- Protect from Moisture: Ensure that the OSB is protected from prolonged exposure to moisture.

Caption: Regular maintenance and care can extend the lifespan of laminated OSB.

9. Environmental Impact of Laminated OSB

Laminated OSB is considered an environmentally friendly building material due to several factors:

- Sustainable Sourcing: OSB is made from fast-growing, renewable wood species.

- Efficient Manufacturing: The manufacturing process of OSB is energy-efficient and generates minimal waste.

- Recyclability: OSB can be recycled and reused in other applications.

- Low VOC Emissions: Laminated OSB emits low levels of volatile organic compounds (VOCs), making it a healthier choice for indoor environments.

10. FAQs About Laminated OSB

Q1: What is the difference between OSB and plywood?

A: OSB is made from compressed wood strands, while plywood is made from thin layers of wood veneer. OSB is generally more cost-effective and has better moisture resistance, while plywood is stronger and more durable.

Q2: Can laminated OSB be used outdoors?

A: Laminated OSB can be used outdoors, but it should be properly sealed and protected from prolonged exposure to moisture.

Q3: How long does laminated OSB last?

A: With proper installation and maintenance, laminated OSB can last for several decades.

Q4: Is laminated OSB fire-resistant?

A: Standard laminated OSB is not fire-resistant, but fire-retardant laminated OSB is available for applications requiring enhanced fire resistance.

Q5: Can laminated OSB be painted?

A: Yes, laminated OSB can be painted, but it should be properly primed and sealed first to ensure good adhesion.

Q6: Is laminated OSB eco-friendly?

A: Yes, laminated OSB is considered eco-friendly due to its sustainable sourcing, efficient manufacturing process, and recyclability.

Q7: What thicknesses are available for laminated OSB?

A: Laminated OSB is available in various thicknesses, typically ranging from 1/4 inch to 1 inch, depending on the application.

Q8: Can laminated OSB be used for flooring?

A: Yes, laminated OSB is commonly used as subflooring and can also be used as a finished flooring material when properly sealed and finished.

Q9: How do I cut laminated OSB?

A: Laminated OSB can be cut using a circular saw, table saw, or handsaw. It is important to use a sharp blade to ensure clean cuts.

Q10: What is the cost of laminated OSB?

A: The cost of laminated OSB varies depending on the thickness, size, and type, but it is generally more affordable than plywood and other building materials.

11. Conclusion

Laminated OSB is a versatile, cost-effective, and durable building material that has become a staple in the construction industry. Its strength, moisture resistance, and ease of installation make it suitable for a wide range of applications, from sheathing and subflooring to roofing and wall panels. With proper installation and maintenance, laminated OSB can provide long-lasting performance and contribute to sustainable building practices.

Whether you’re a builder, contractor, or homeowner, laminated OSB offers a reliable and eco-friendly solution for your construction needs. By understanding its benefits, applications, and installation tips, you can make informed decisions and achieve the best results for your projects.

Note: The images and captions used in this article are for illustrative purposes only. Please replace the placeholder image URLs with actual images relevant to the content. Additionally, ensure that the article is optimized for SEO by including relevant keywords, meta descriptions, and alt text for images.