The Ultimate Guide to Thinck MDF (Medium Density Fiberboard)

Introduction to Thinck MDF

Thinck MDF Medium Density Fiberboard, commonly known as MDF, is a versatile and widely used engineered wood product. Thinck MDF, a premium brand in the MDF market, has gained popularity for its high-quality, durability, and eco-friendly properties. Whether you’re a DIY enthusiast, a professional carpenter, or an architect, understanding the benefits and applications of Thinck MDF can help you make informed decisions for your projects.

In this comprehensive guide, we’ll explore everything you need to know about Thinck MDF, including its properties, uses, advantages, and disadvantages. We’ll also provide tips on how to work with Thinck MDF, answer frequently asked questions, and showcase real-life applications.

What is Thinck MDF?

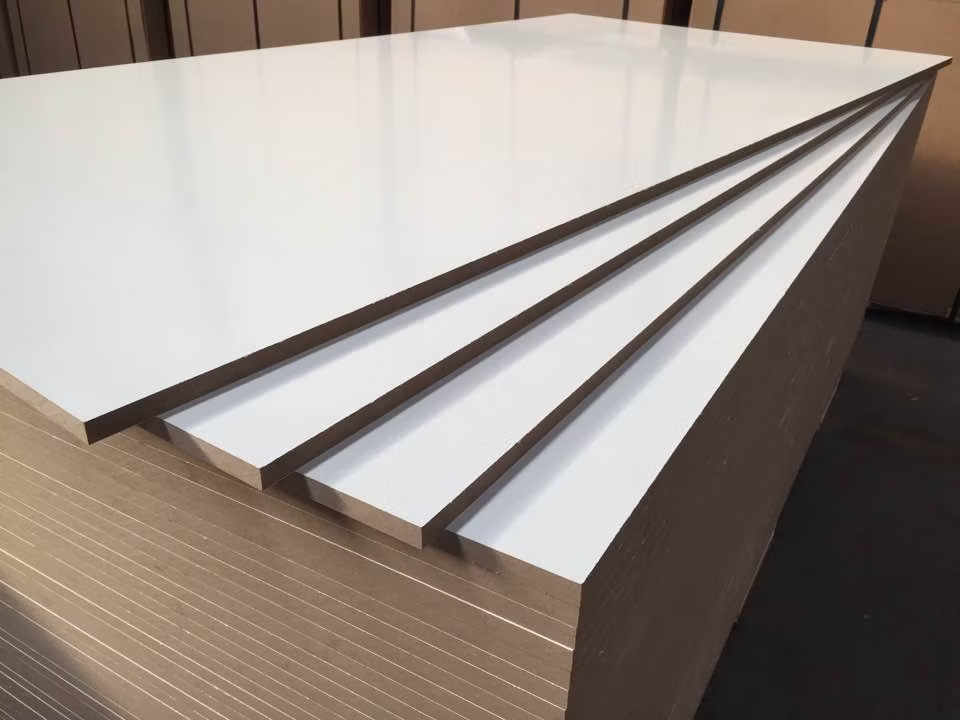

Thinck MDF is a type of medium-density fiberboard made from wood fibers, resin, and wax. It is manufactured by compressing these materials under high pressure and temperature to create a dense, uniform board. Unlike natural wood, Thinck MDF has no grain, making it easy to cut, shape, and finish.

Key Features of Thinck MDF:

- Smooth Surface: Ideal for painting and veneering.

- Uniform Density: Ensures consistent performance.

- Eco-Friendly: Made from recycled wood fibers and sustainable materials.

- Cost-Effective: More affordable than solid wood.

Advantages of Thinck MDF

1. Versatility

Thinck MDF can be used for a wide range of applications, from furniture and cabinetry to wall paneling and flooring. Its smooth surface makes it perfect for painting, while its uniform density allows for precise cutting and shaping.

2. Durability

Thinck MDF is highly durable and resistant to warping or cracking. It is less prone to expansion and contraction compared to natural wood, making it ideal for environments with fluctuating humidity levels.

3. Eco-Friendly

Thinck MDF is manufactured using recycled wood fibers and sustainable practices, making it an environmentally friendly choice for conscientious consumers.

4. Cost-Effective

Compared to solid wood, Thinck MDF is more affordable while still offering excellent performance and aesthetics.

5. Easy to Work With

Thinck MDF can be easily cut, drilled, and shaped using standard woodworking tools. Its smooth surface also makes it easy to paint or laminate.

Disadvantages of Thinck MDF

1. Susceptibility to Moisture

While Thinck MDF is durable, it is not waterproof. Prolonged exposure to moisture can cause swelling or damage. To mitigate this, use moisture-resistant MDF for areas prone to dampness.

2. Weight

Thinck MDF is denser and heavier than natural wood, which can make handling and transportation more challenging.

3. Dust During Cutting

Cutting Thinck MDF generates fine dust, which can be harmful if inhaled. Always wear a mask and work in a well-ventilated area.

Applications of Thinck MDF

1. Furniture Making

Thinck MDF is widely used in the production of furniture, including cabinets, shelves, and tables. Its smooth surface makes it ideal for painting or applying veneers.

2. Cabinetry

Kitchen and bathroom cabinets are often made from Thinck MDF due to its durability and ease of customization.

3. Wall Paneling

Thinck MDF can be used to create decorative wall panels, adding texture and style to interior spaces.

4. Flooring

Thinck MDF is sometimes used as an underlayment for flooring, providing a smooth and stable surface.

5. DIY Projects

From picture frames to storage boxes, Thinck MDF is a favorite material for DIY enthusiasts.

How to Work with Thinck MDF

1. Cutting

Use a circular saw or jigsaw with a fine-tooth blade for clean cuts. Always wear a mask to avoid inhaling dust.

2. Sanding

Sand the edges of Thinck MDF with fine-grit sandpaper to achieve a smooth finish.

3. Painting

Apply a primer before painting to ensure even coverage. Thinck MDF’s smooth surface allows for a flawless finish.

4. Sealing

To protect Thinck MDF from moisture, seal the edges with a waterproof sealant.

Tips for Choosing the Right Thinck MDF

- Consider the Application: Choose moisture-resistant MDF for bathrooms or kitchens.

- Check the Density: Higher density MDF is more durable and suitable for heavy-duty applications.

- Look for Certifications: Ensure the MDF is certified by relevant environmental standards.

Frequently Asked Questions (FAQs)

1. Is Thinck MDF eco-friendly?

Yes, Thinck MDF is made from recycled wood fibers and sustainable materials, making it an eco-friendly choice.

2. Can Thinck MDF be used outdoors?

No, Thinck MDF is not suitable for outdoor use as it is not waterproof.

3. How do I prevent Thinck MDF from swelling?

Use moisture-resistant MDF and seal the edges with a waterproof sealant.

4. Is Thinck MDF safe for furniture?

Yes, Thinck MDF is safe for furniture and is widely used in the industry.

5. Can I paint Thinck MDF?

Yes, Thinck MDF’s smooth surface makes it ideal for painting. Always apply a primer first.

Real-Life Applications of Thinck MDF

Case Study 1: Modern Kitchen Cabinets

A homeowner chose Thinck MDF for their kitchen cabinets due to its durability and smooth finish. The cabinets were painted in a sleek white color, giving the kitchen a modern and elegant look.

Case Study 2: DIY Bookshelf

A DIY enthusiast used Thinck MDF to create a custom bookshelf. The material was easy to cut and paint, resulting in a stylish and functional piece of furniture.

Conclusion

Thinck MDF is a versatile, durable, and cost-effective material that is perfect for a wide range of applications. Whether you’re a professional or a DIY enthusiast, Thinck MDF offers endless possibilities for your projects. By understanding its properties, advantages, and limitations, you can make the most of this remarkable material.

Additional Resources

- How to Cut MDF Safely

- Top 10 MDF Projects for Beginners

- Eco-Friendly Building Materials: A Comprehensive Guide

By incorporating Thinck MDF into your next project, you can achieve professional-quality results while staying within budget. Happy building!