The Ultimate Guide to Shuttering Plywood: Uses, Benefits, and FAQs.

Shuttering plywood, also known as formwork plywood, is a specialized type of plywood designed for use in concrete formwork. It is an essential material in the construction industry, particularly for creating molds or forms into which concrete is poured to achieve the desired shape and structure. This article delves into the various aspects of shuttering plywood, including its uses, benefits, types, and frequently asked questions.

Table of Contents

- What is Shuttering Plywood?

- Types of Shuttering Plywood

- Uses of Shuttering Plywood

- Benefits of Shuttering Plywood

- How to Choose the Right Shuttering Plywood

- Installation and Maintenance Tips

- Environmental Considerations

- FAQs

1. What is Shuttering Plywood?

Shuttering plywood is a high-strength, durable plywood specifically designed for use in concrete formwork. It is made from multiple layers of wood veneers bonded together with waterproof adhesives, making it resistant to moisture and capable of withstanding the pressure exerted by wet concrete.

Key Characteristics:

- High Strength: Capable of supporting heavy loads.

- Moisture Resistance: Treated to withstand exposure to water and humidity.

- Smooth Surface: Provides a smooth finish to the concrete.

- Reusability: Can be used multiple times if maintained properly.

2. Types of Shuttering Plywood

There are several types of shuttering plywood available, each suited for different applications and conditions.

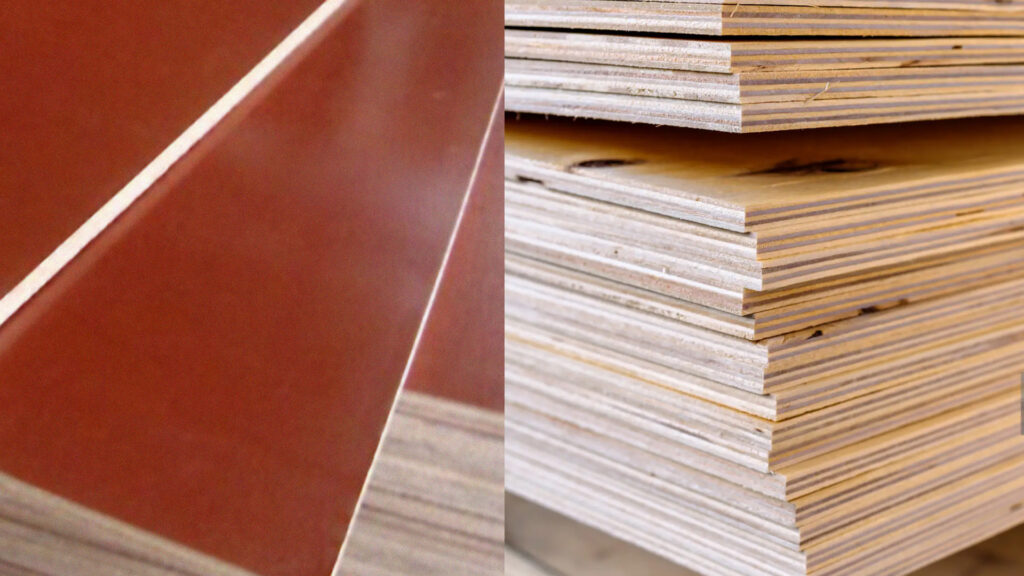

a. Film-Faced Shuttering Plywood

This type is coated with a phenolic film on both sides, providing extra protection against moisture and wear. It is the most commonly used type in construction.

b. Marine Plywood

Although not specifically designed for shuttering, marine plywood is highly resistant to water and can be used in formwork, especially in harsh environments.

c. Standard Shuttering Plywood

This is a basic type of shuttering plywood without any special coatings. It is suitable for less demanding applications.

d. Overlaid Shuttering Plywood

This type has a resin overlay that enhances its durability and resistance to abrasion, making it ideal for high-use scenarios.

3. Uses of Shuttering Plywood

Shuttering plywood is versatile and finds applications in various construction projects.

a. Concrete Formwork

The primary use of shuttering plywood is in creating molds for concrete structures such as walls, columns, beams, and slabs.

b. Bridge Construction

Due to its strength and durability, it is often used in the construction of bridges and other large infrastructure projects.

c. Tunnel Linings

Shuttering plywood is also used in the construction of tunnels, where it helps in shaping the concrete linings.

d. Residential Construction

It is commonly used in residential projects for foundations, driveways, and other concrete elements.

4. Benefits of Shuttering Plywood

Shuttering plywood offers several advantages that make it a preferred choice in construction.

a. Cost-Effective

It is relatively inexpensive compared to other formwork materials like steel, making it a cost-effective option.

b. Reusable

With proper care, shuttering plywood can be reused multiple times, reducing overall project costs.

c. Easy to Handle

It is lightweight and easy to cut and shape, making it convenient to work with on-site.

d. High Strength

It can withstand the pressure exerted by wet concrete, ensuring the integrity of the formwork.

e. Smooth Finish

The smooth surface of shuttering plywood results in a high-quality finish on the concrete.

5. How to Choose the Right Shuttering Plywood

Selecting the right shuttering plywood is crucial for the success of your project. Here are some factors to consider:

a. Project Requirements

Consider the size, shape, and complexity of the concrete structure you are building.

b. Environmental Conditions

Choose plywood that can withstand the specific environmental conditions of your project site, such as humidity or temperature extremes.

c. Budget

While shuttering plywood is generally cost-effective, prices can vary based on type and quality. Choose one that fits your budget without compromising on quality.

d. Reusability

If you plan to reuse the plywood, opt for a type that is known for its durability and resistance to wear.

e. Supplier Reputation

Purchase from a reputable supplier to ensure you get high-quality, reliable shuttering plywood.

6. Installation and Maintenance Tips

Proper installation and maintenance are key to maximizing the lifespan and effectiveness of shuttering plywood.

a. Installation Tips

- Ensure the plywood is properly aligned and securely fastened to prevent leaks or misalignment.

- Use appropriate supports and bracing to handle the weight of the concrete.

- Apply a release agent to the plywood surface to facilitate easy removal after the concrete sets.

b. Maintenance Tips

- Clean the plywood after each use to remove any concrete residue.

- Inspect for damage and repair or replace any damaged sections.

- Store in a dry, covered area to prevent moisture damage.

7. Environmental Considerations

As with any construction material, it’s important to consider the environmental impact of shuttering plywood.

a. Sustainability

Opt for plywood sourced from sustainably managed forests to minimize environmental impact.

b. Recycling

Shuttering plywood can often be recycled or repurposed after its use in formwork, reducing waste.

c. Eco-Friendly Alternatives

Consider using eco-friendly alternatives like bamboo plywood, which is renewable and has a lower environmental footprint.

8. FAQs

Q1: What is the difference between shuttering plywood and regular plywood?

A: Shuttering plywood is specifically designed for use in concrete formwork, with properties like high strength, moisture resistance, and a smooth surface. Regular plywood may not have these specialized features.

Q2: How many times can shuttering plywood be reused?

A: With proper maintenance, shuttering plywood can be reused 10-20 times, depending on the type and conditions of use.

Q3: Can shuttering plywood be used for outdoor projects?

A: Yes, especially types like film-faced or marine plywood, which are designed to withstand outdoor conditions.

Q4: What is the lifespan of shuttering plywood?

A: The lifespan varies based on usage and maintenance, but high-quality shuttering plywood can last for several years.

Q5: Is shuttering plywood environmentally friendly?

A: It can be, especially if sourced from sustainable forests and recycled or repurposed after use.

Q6: How do I maintain shuttering plywood?

A: Clean it after each use, inspect for damage, and store it in a dry, covered area to extend its lifespan.

Q7: Can shuttering plywood be cut to size?

A: Yes, it can be easily cut and shaped to fit the specific requirements of your project.

Q8: What is the cost of shuttering plywood?

A: The cost varies based on type and quality, but it is generally more cost-effective than other formwork materials like steel.

Q9: Can shuttering plywood be used for curved structures?

A: Yes, it can be bent or shaped to create curved forms, although this may require specialized techniques.

Q10: What are the alternatives to shuttering plywood?

A: Alternatives include steel formwork, aluminum formwork, and eco-friendly options like bamboo plywood.

Conclusion

Shuttering plywood is an indispensable material in the construction industry, offering a blend of strength, durability, and cost-effectiveness. Whether you’re working on a small residential project or a large infrastructure development, understanding the types, uses, and benefits of shuttering plywood can help you make informed decisions and achieve the best results. By following proper installation and maintenance practices, you can maximize the lifespan of your shuttering plywood and contribute to more sustainable construction practices.