Commercial Plywood: A Comprehensive Guide

Table of Contents

- Introduction to Commercial Plywood

- History and Evolution of Plywood

- Types of Commercial Plywood

- Manufacturing Process of Plywood

- Grades and Specifications of Plywood

- Applications of Commercial Plywood

- Advantages and Disadvantages of Commercial Plywood

- Sustainability and Environmental Impact

- Maintenance and Care of Plywood

- Future Trends in the Plywood Industry

- FAQs

1. Introduction to Commercial Plywood

Commercial plywood is a versatile and widely used building material that has become a staple in construction, furniture making, and various other industries. It is made by bonding together thin layers of wood veneers with adhesive, creating a strong and durable sheet material. Plywood is known for its strength, stability, and resistance to cracking, warping, and shrinking, making it an ideal choice for a wide range of applications.

In this article, we will explore the history, types, manufacturing process, grades, applications, advantages, and disadvantages of commercial plywood. We will also discuss its environmental impact, maintenance, and future trends in the industry.

2. History and Evolution of Plywood

The concept of plywood dates back to ancient times. The Egyptians and Greeks used laminated wood for furniture and other applications. However, modern plywood as we know it today began to take shape in the 19th century with the advent of industrial machinery and adhesives.

The first patent for plywood was issued in 1865 to John K. Mayo, who developed a method for producing laminated wood products. The early 20th century saw significant advancements in plywood manufacturing, particularly during World War I and World War II, when plywood was used extensively for military applications such as aircraft construction and shipbuilding.

Post-war, the plywood industry expanded rapidly, driven by the demand for affordable and durable building materials. Today, plywood is a global industry, with millions of cubic meters produced annually.

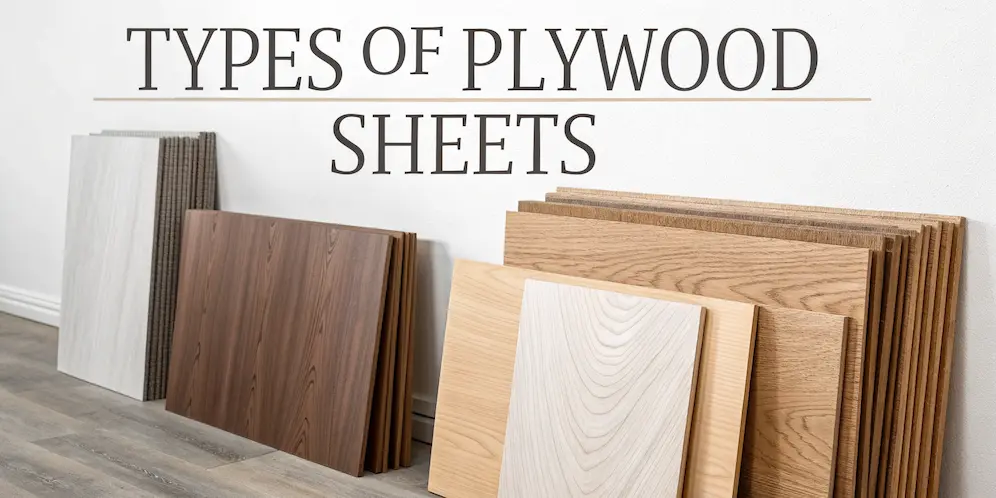

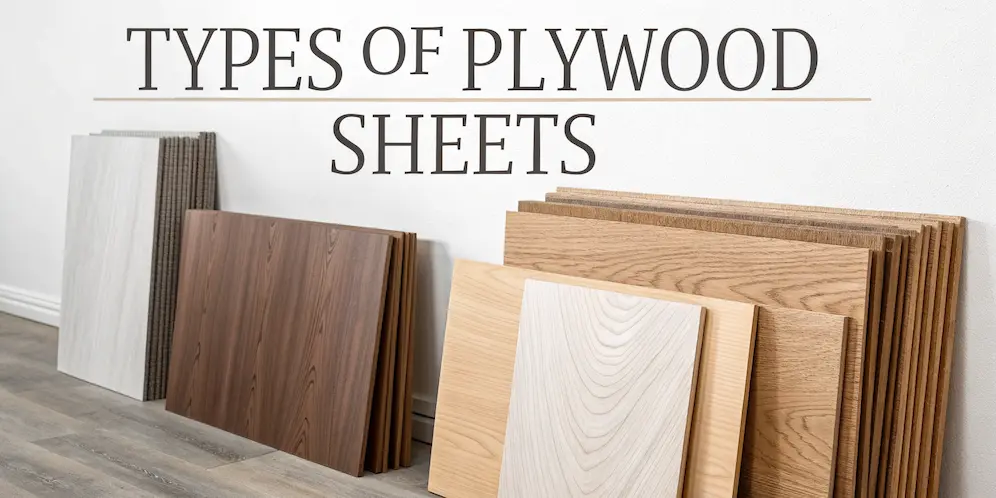

3. Types of Commercial Plywood

Commercial plywood comes in various types, each designed for specific applications. The most common types include:

3.1. Softwood Plywood

Softwood plywood is made from softwood veneers such as pine, cedar, or spruce. It is commonly used in construction for roofing, flooring, and wall sheathing.

3.2. Hardwood Plywood

Hardwood plywood is made from hardwood veneers such as oak, maple, or birch. It is used in furniture making, cabinetry, and decorative applications.

3.3. Marine Plywood

Marine plywood is specially designed for use in wet or humid environments. It is made with waterproof adhesives and high-quality veneers, making it resistant to rot and fungal attacks.

3.4. Structural Plywood

Structural plywood is used in load-bearing applications such as beams, columns, and flooring. It is engineered to meet specific strength and durability requirements.

3.5. Decorative Plywood

Decorative plywood is used for aesthetic purposes, often featuring attractive wood grains or finishes. It is commonly used in interior design, paneling, and furniture.

3.6. Flexible Plywood

Flexible plywood, also known as bendable plywood, is designed to be easily bent and shaped. It is used in curved furniture, arches, and other applications requiring flexibility.

4. Manufacturing Process of Plywood

The manufacturing process of plywood involves several key steps:

4.1. Log Selection

The process begins with the selection of suitable logs. The logs are chosen based on their species, size, and quality.

4.2. Peeling the Veneers

The selected logs are then debarked and cut into manageable lengths. They are then placed in a lathe, where they are rotated against a blade to peel off thin layers of wood, known as veneers.

4.3. Drying the Veneers

The peeled veneers are dried in a kiln to reduce their moisture content. This step is crucial to ensure the stability and strength of the final product.

4.4. Gluing and Layering

The dried veneers are then coated with adhesive and layered together. The layers are arranged with the grain direction alternating at 90-degree angles to each other, which enhances the strength and stability of the plywood.

4.5. Pressing

The layered veneers are placed in a hot press, where they are subjected to high pressure and temperature. This process bonds the layers together and cures the adhesive.

4.6. Trimming and Finishing

The pressed plywood sheets are trimmed to the desired size and sanded to achieve a smooth surface. They may also be treated with coatings or finishes depending on the intended application.

5. Grades and Specifications of Plywood

Plywood is graded based on several factors, including the quality of the veneers, the type of adhesive used, and the intended application. The most common grading systems include:

5.1. A-Grade Plywood

A-Grade plywood is the highest quality, with a smooth, knot-free surface. It is used for high-end furniture and decorative applications.

5.2. B-Grade Plywood

B-Grade plywood has a few minor defects, such as small knots or patches. It is suitable for applications where appearance is less critical, such as cabinetry.

5.3. C-Grade Plywood

C-Grade plywood has more noticeable defects, such as larger knots and splits. It is commonly used in construction for structural applications.

5.4. D-Grade Plywood

D-Grade plywood has the most defects and is typically used for non-structural applications where appearance is not important.

5.5. Marine Grade Plywood

Marine grade plywood is specially graded for use in wet environments. It is made with waterproof adhesives and high-quality veneers to ensure durability and resistance to moisture.

6. Applications of Commercial Plywood

Commercial plywood is used in a variety of applications across different industries. Some of the most common applications include:

6.1. Construction

Plywood is widely used in construction for roofing, flooring, wall sheathing, and formwork. Its strength and stability make it an ideal material for structural applications.

6.2. Furniture Making

Plywood is a popular choice for furniture making due to its strength, durability, and versatility. It is used to make everything from cabinets and shelves to tables and chairs.

6.3. Interior Design

Plywood is often used in interior design for paneling, partitions, and decorative elements. Its smooth surface and attractive wood grains make it a popular choice for creating stylish and modern interiors.

6.4. Packaging

Plywood is used in the packaging industry to create crates, boxes, and pallets. Its strength and durability make it ideal for protecting goods during transportation.

6.5. Automotive Industry

Plywood is used in the automotive industry for making interior panels, flooring, and other components. Its lightweight and strength make it a suitable material for vehicle construction.

6.6. Marine Industry

Marine plywood is used in boat building and other marine applications. Its resistance to moisture and rot makes it ideal for use in wet environments.

7. Advantages and Disadvantages of Commercial Plywood

7.1. Advantages of Commercial Plywood

- Strength and Durability: Plywood is stronger and more durable than solid wood, making it ideal for structural applications.

- Stability: Plywood is less prone to warping, cracking, and shrinking compared to solid wood.

- Versatility: Plywood can be used in a wide range of applications, from construction to furniture making.

- Cost-Effective: Plywood is generally more affordable than solid wood, making it a cost-effective option for many projects.

- Eco-Friendly: Plywood is made from renewable resources and can be recycled, making it an environmentally friendly choice.

7.2. Disadvantages of Commercial Plywood

- Susceptibility to Moisture: While marine plywood is resistant to moisture, standard plywood can be susceptible to water damage if not properly treated.

- Formaldehyde Emissions: Some plywood products may emit formaldehyde, a harmful chemical, especially if low-quality adhesives are used.

- Limited Aesthetic Appeal: While decorative plywood is available, standard plywood may not have the same aesthetic appeal as solid wood.

8. Sustainability and Environmental Impact

The plywood industry has made significant strides in recent years to reduce its environmental impact. Sustainable forestry practices, such as selective logging and reforestation, help ensure that the wood used in plywood production is sourced responsibly.

Additionally, many manufacturers are now using low-emission adhesives and finishes to reduce the release of harmful chemicals into the environment. Recycling and reusing plywood products also contribute to reducing waste and conserving resources.

However, challenges remain, particularly in regions where illegal logging and deforestation are prevalent. Consumers can play a role in promoting sustainability by choosing plywood products that are certified by organizations such as the Forest Stewardship Council (FSC) or the Programme for the Endorsement of Forest Certification (PEFC).

9. Maintenance and Care of Plywood

Proper maintenance and care are essential to ensure the longevity and performance of plywood products. Here are some tips for maintaining plywood:

9.1. Cleaning

Regularly clean plywood surfaces with a soft cloth or sponge and mild detergent. Avoid using harsh chemicals or abrasive cleaners, as they can damage the surface.

9.2. Sealing

Seal plywood surfaces with a protective coating, such as varnish or paint, to protect them from moisture and UV damage. This is especially important for outdoor applications.

9.3. Repairing

Inspect plywood regularly for signs of damage, such as cracks or delamination. Repair any damage promptly to prevent further deterioration.

9.4. Storing

Store plywood in a dry, well-ventilated area to prevent moisture absorption. Keep it off the ground and cover it with a tarp if stored outdoors.

10. Future Trends in the Plywood Industry

The plywood industry is constantly evolving, driven by advancements in technology, materials, and sustainability practices. Some of the key trends shaping the future of the industry include:

10.1. Engineered Wood Products

Engineered wood products, such as cross-laminated timber (CLT) and laminated veneer lumber (LVL), are gaining popularity as alternatives to traditional plywood. These products offer enhanced strength, stability, and sustainability.

10.2. Digitalization and Automation

Digitalization and automation are transforming the plywood manufacturing process, improving efficiency, precision, and quality control. Advanced machinery and robotics are being used to streamline production and reduce waste.

10.3. Sustainable Practices

Sustainability will continue to be a major focus in the plywood industry. Manufacturers are increasingly adopting eco-friendly practices, such as using recycled materials, reducing emissions, and sourcing wood from certified forests.

10.4. Innovative Applications

Plywood is being used in innovative applications, such as modular construction, 3D printing, and renewable energy projects. These new applications are expanding the market for plywood and driving demand for high-performance products.

11. FAQs

11.1. What is commercial plywood?

Commercial plywood is a type of engineered wood product made by bonding together thin layers of wood veneers with adhesive. It is widely used in construction, furniture making, and other industries due to its strength, durability, and versatility.

11.2. What are the different types of plywood?

The different types of plywood include softwood plywood, hardwood plywood, marine plywood, structural plywood, decorative plywood, and flexible plywood. Each type is designed for specific applications.

11.3. How is plywood made?

Plywood is made by peeling thin layers of wood veneers from logs, drying them, coating them with adhesive, layering them together, pressing them under high pressure and temperature, and then trimming and finishing the sheets.

11.4. What are the grades of plywood?

Plywood is graded based on the quality of the veneers and the intended application. Common grades include A-Grade, B-Grade, C-Grade, D-Grade, and Marine Grade.

11.5. Is plywood environmentally friendly?

Plywood can be environmentally friendly if it is made from sustainably sourced wood and low-emission adhesives. Look for certifications such as FSC or PEFC to ensure the plywood is produced responsibly.

11.6. How do I maintain plywood?

To maintain plywood, clean it regularly with mild detergent, seal it with a protective coating, repair any damage promptly, and store it in a dry, well-ventilated area.

11.7. What are the future trends in the plywood industry?

Future trends in the plywood industry include the use of engineered wood products, digitalization and automation, sustainable practices, and innovative applications in construction and other industries.