MDF (Medium-Density Fiberboard)

Comprehensive Guide to MDF (Medium-Density Fiberboard)

Medium-Density Fiberboard, commonly known as MDF, is a versatile and cost-effective material used extensively in furniture making, cabinetry, construction, and decorative projects. This guide explores MDF in depth, covering its production, uses, benefits, drawbacks, comparisons with other materials, and frequently asked questions.

Table of Contents:

-

What is MDF?

-

How is MDF Made?

-

Types of MDF

-

Applications of MDF

-

Advantages of Using MDF

-

Drawbacks of MDF

-

MDF vs. Other Materials

-

Sustainability and Environmental Impact

-

FAQs About MDF

1. What is MDF?

Medium-Density Fiberboard (MDF) is an engineered wood product made from wood fibers combined with resin and compressed under high pressure. Unlike natural wood, MDF does not have a grain and offers a smooth, uniform surface ideal for various applications.

MDF is classified between particleboard and plywood in terms of density and strength. Its affordability and versatility make it a preferred choice for manufacturers and DIY enthusiasts.

2. How is MDF Made?

The manufacturing process of MDF involves several steps to ensure consistency and quality:

Step 1: Raw Material Preparation

Wood remnants, such as sawdust, chips, and fibers, are collected from other woodworking processes. These remnants are processed and cleaned to remove impurities.

Step 2: Fiberization

The wood remnants are broken down into fine fibers using steam and mechanical refining. This step creates the base material for MDF.

Step 3: Resin Application

The wood fibers are mixed with a synthetic resin adhesive, often urea-formaldehyde, and other additives to enhance the board’s properties.

Step 4: Compression

The resin-coated fibers are heated and compressed into sheets under high pressure. This process eliminates air pockets and ensures the board’s density and smooth surface.

Step 5: Finishing and Cutting

The sheets are cooled, trimmed to size, and sanded to achieve a smooth finish.

3. Types of MDF

Several types of MDF cater to specific needs:

-

Standard MDF

Used for general purposes such as furniture and shelving.

-

Moisture-Resistant MDF (MR MDF)

Treated to withstand high humidity, ideal for kitchens and bathrooms.

-

Fire-Resistant MDF

Contains fire-retardant chemicals, suitable for use in public buildings.

-

Ultra-Light MDF (ULDF)

A lightweight version used for decorative applications.

-

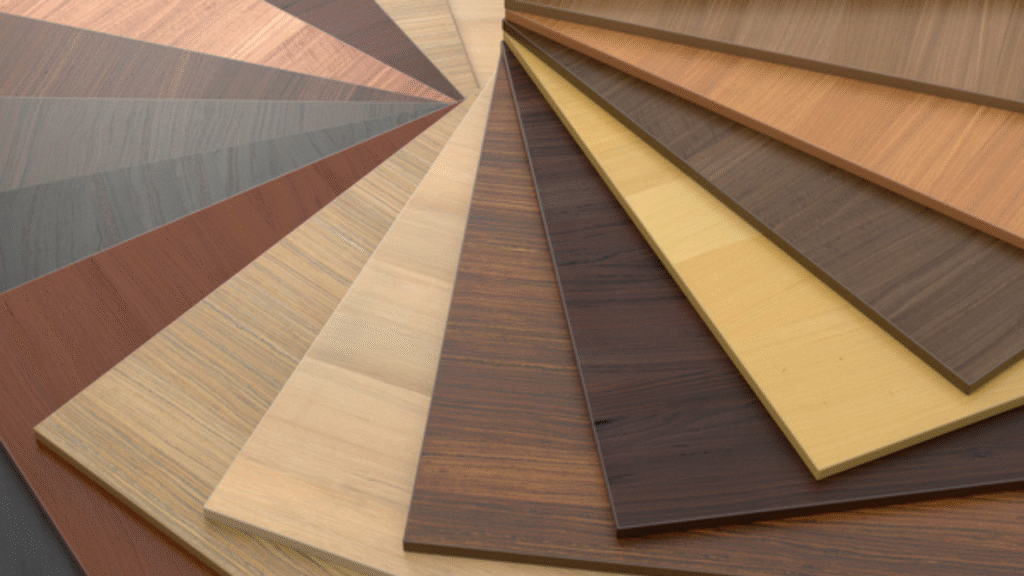

Laminated MDF

Coated with decorative laminates or veneers for aesthetic appeal.

4. Applications of MDF

MDF is widely used in various industries due to its adaptability:

-

Furniture Making

MDF is a go-to material for manufacturing affordable furniture, including tables, cabinets, and bookshelves.

-

Cabinetry and Joinery

Its smooth surface is perfect for creating detailed designs in cabinets and moldings.

-

Construction

MDF panels are used for wall paneling, partitions, and flooring underlayment.

-

Decorative Projects

Artists and crafters use MDF for creating decorative items like photo frames and carvings.

-

Soundproofing

Due to its density, MDF is effective in soundproofing applications.

5. Advantages of Using MDF

MDF offers several benefits that make it a popular choice:

-

Affordability

MDF is less expensive than natural wood and plywood, making it an economical choice.

-

Smooth Surface

Its even texture is perfect for painting, veneering, or laminating.

-

Versatility

MDF can be cut, routed, and shaped with ease, enabling intricate designs.

-

Consistency

Unlike natural wood, MDF does not have knots, grain, or voids, ensuring uniformity.

-

Availability

MDF is readily available in various thicknesses and sizes.

6. Drawbacks of MDF

Despite its advantages, MDF has some limitations:

-

Susceptibility to Water Damage

Standard MDF swells and weakens when exposed to moisture.

-

Weakness in Holding Screws

MDF does not hold screws as effectively as natural wood.

-

Health Concerns

The urea-formaldehyde resin used in MDF can release volatile organic compounds (VOCs).

-

Heaviness

MDF is denser and heavier than many other materials, posing challenges in handling and transportation.

7. MDF vs. Other Materials

MDF vs. Plywood

-

Cost: MDF is more affordable than plywood.

-

Strength: Plywood is stronger and more durable.

-

Workability: MDF is easier to cut and shape.

MDF vs. Particleboard

-

Density: MDF is denser and stronger than particleboard.

-

Surface Finish: MDF has a smoother surface, suitable for painting.

MDF vs. Solid Wood

-

Cost: MDF is cheaper than solid wood.

-

Appearance: Solid wood offers natural aesthetics, whereas MDF requires finishing.

8. Sustainability and Environmental Impact

Pros:

-

MDF repurposes wood waste, reducing deforestation.

-

It is recyclable and can be reused in other products.

Cons:

-

The production process involves chemicals like formaldehyde, contributing to environmental concerns.

-

Disposal of MDF must be handled carefully to avoid harmful emissions.

9. FAQs About MDF

Q1. Is MDF stronger than plywood?

No, plywood is generally stronger due to its cross-grain structure, making it suitable for heavy-duty applications.

Q2. Can MDF be waterproofed?

Yes, moisture-resistant MDF is designed for high-humidity areas, and additional waterproof coatings can enhance its resistance.

Q3. Is MDF safe for indoor use?

MDF is safe if sealed properly to prevent the release of formaldehyde. Look for MDF with low-emission certifications.

Q4. How do you paint MDF?

Use a primer designed for MDF to seal the surface, followed by a water-based or oil-based paint for a smooth finish.

Q5. Can MDF be used outdoors?

MDF is not suitable for outdoor use unless specially treated, as it can absorb moisture and deteriorate.

Q6. Is MDF environmentally friendly?

MDF uses wood waste and is recyclable, but the chemicals used in its production can pose environmental concerns.

Q7. How do I clean MDF furniture?

Use a damp cloth with mild detergent. Avoid soaking MDF as it can cause swelling.

Q8. What is the lifespan of MDF?

With proper care and usage, MDF can last for several decades, though its longevity depends on the environment and application.

Q9. Can MDF be repaired if damaged?

Minor chips and scratches can be filled with wood filler, sanded, and repainted.

Q10. Is MDF a good choice for DIY projects?

Yes, MDF is affordable, easy to work with, and offers a smooth surface ideal for creative DIY projects.