The Comprehensive Guide to Euro 2 Pallets: Everything You Need to Know

Euro 2 Pallet, Pallets are an essential component of the global supply chain, serving as the foundation for the storage and transportation of goods. Among the various types of pallets available, the Euro pallet stands out as one of the most widely used and recognized standards in Europe and beyond. In this article, we will delve deep into the specifics of the Euro 2 pallet, exploring its design, dimensions, uses, advantages, and much more. By the end of this comprehensive guide, you will have a thorough understanding of the Euro 2 pallet and its significance in the logistics and supply chain industry.

Table of Contents

- What is a Euro 2 Pallet?

- History and Evolution of Euro Pallets

- Design and Dimensions of Euro 2 Pallets

- Materials Used in Euro 2 Pallets

- Load Capacity and Durability

- Advantages of Using Euro 2 Pallets

- Common Uses of Euro 2 Pallets

- Comparison with Other Euro Pallet Types

- Sustainability and Environmental Impact

- Maintenance and Repair of Euro 2 Pallets

- Regulations and Standards

- Cost Analysis: Euro 2 Pallets vs. Other Pallets

- Future Trends in Pallet Design and Usage

- Conclusion

1. What is a Euro 2 Pallet?

The Euro 2 pallet is a specific type of Euro pallet that adheres to the standards set by the European Pallet Association (EPAL). Euro pallets are designed to be uniform in size and structure, ensuring compatibility with various handling equipment, storage systems, and transportation methods. The Euro 2 pallet, in particular, is one of the several sizes within the Euro pallet family, each designed to meet different logistical needs.

The Euro 2 pallet is characterized by its specific dimensions, load capacity, and construction, which make it suitable for a wide range of applications, from warehousing to international shipping. Its standardized design ensures that it can be easily integrated into existing supply chains, reducing the need for custom solutions and improving overall efficiency.

2. History and Evolution of Euro Pallets

The concept of the Euro pallet was first introduced in the 1960s by the European Railway Association (UIC) to standardize pallet sizes and improve the efficiency of goods transportation across Europe. The goal was to create a uniform pallet that could be used interchangeably across different countries and industries, reducing the need for multiple pallet types and simplifying logistics.

Over the years, the Euro pallet has evolved to meet the changing needs of the supply chain industry. The Euro 2 pallet, along with other sizes such as the Euro 1, Euro 3, and Euro 6, was developed to provide a range of options for different types of goods and transportation methods. Today, Euro pallets are used not only in Europe but also in other parts of the world, thanks to their reliability and versatility.

3. Design and Dimensions of Euro 2 Pallets

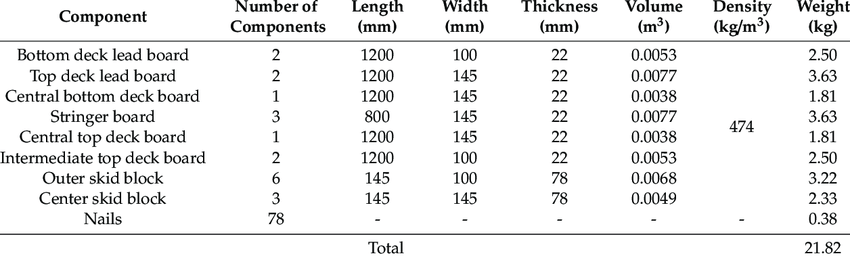

The Euro 2 pallet is designed to meet specific dimensional standards, ensuring compatibility with various handling equipment and storage systems. The standard dimensions of a Euro 2 pallet are 1200mm x 1000mm, making it slightly narrower than the Euro 1 pallet, which measures 1200mm x 800mm. This size difference allows the Euro 2 pallet to accommodate different types of goods and packaging configurations.

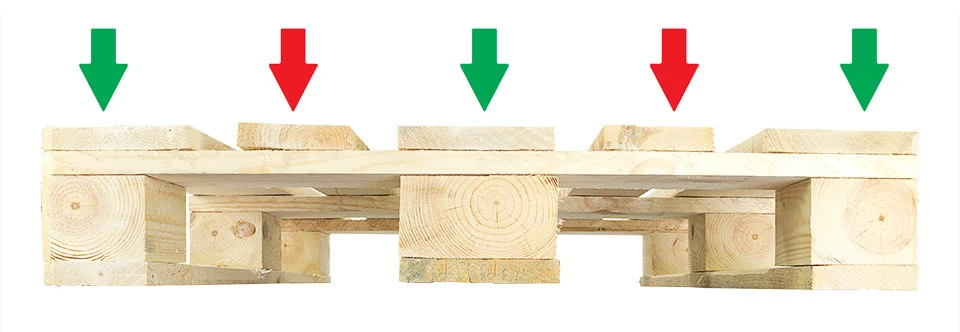

The Euro 2 pallet features a four-way entry design, meaning that it can be accessed by forklifts and pallet jacks from all four sides. This design enhances the pallet’s versatility and makes it easier to handle in various environments, from warehouses to shipping docks.

The pallet is constructed using a combination of wooden boards and blocks, which are arranged in a specific pattern to provide optimal strength and stability. The top deck boards are spaced to allow for proper airflow and drainage, which is particularly important when transporting goods that are sensitive to moisture.

4. Materials Used in Euro 2 Pallets

The Euro 2 pallet is typically made from high-quality wood, which provides the necessary strength and durability to withstand the rigors of transportation and storage. The most commonly used wood types include pine, spruce, and fir, which are known for their strength-to-weight ratio and resistance to wear and tear.

The wood used in Euro 2 pallets is usually treated to prevent pest infestations and to enhance its durability. The most common treatment method is heat treatment, which involves heating the wood to a specific temperature to eliminate any pests or pathogens. This treatment is in compliance with the International Standards for Phytosanitary Measures (ISPM 15), which regulates the international movement of wooden packaging materials.

In addition to wood, some Euro 2 pallets may also incorporate other materials, such as plastic or metal, for specific applications. However, wooden pallets remain the most popular choice due to their cost-effectiveness, recyclability, and ease of repair.

5. Load Capacity and Durability

One of the key features of the Euro 2 pallet is its impressive load capacity. The standard Euro 2 pallet is designed to support a static load of up to 7,500 kg and a dynamic load of up to 1,500 kg. This makes it suitable for a wide range of goods, from lightweight consumer products to heavy industrial equipment.

The durability of the Euro 2 pallet is another important factor that contributes to its popularity. The pallet’s construction, which includes reinforced corners and sturdy deck boards, ensures that it can withstand the stresses of repeated use and handling. Additionally, the use of high-quality wood and proper treatment methods further enhances the pallet’s longevity.

However, it’s important to note that the load capacity and durability of a Euro 2 pallet can be affected by factors such as the condition of the pallet, the type of goods being transported, and the handling methods used. Regular inspection and maintenance are essential to ensure that the pallet remains in good condition and continues to perform as expected.

6. Advantages of Using Euro 2 Pallets

The Euro 2 pallet offers several advantages that make it a preferred choice for many businesses. Some of the key benefits include:

- Standardization: The Euro 2 pallet’s standardized dimensions and design ensure compatibility with various handling equipment and storage systems, reducing the need for custom solutions and improving overall efficiency.

- Versatility: The four-way entry design and robust construction make the Euro 2 pallet suitable for a wide range of applications, from warehousing to international shipping.

- Cost-Effectiveness: The use of high-quality wood and efficient manufacturing processes make the Euro 2 pallet an affordable option for businesses of all sizes.

- Sustainability: Wooden Euro 2 pallets are recyclable and can be repaired, reducing their environmental impact and making them a sustainable choice for businesses looking to minimize their carbon footprint.

- Durability: The Euro 2 pallet’s sturdy construction and load capacity ensure that it can withstand the rigors of repeated use and handling, making it a reliable choice for long-term use.

7. Common Uses of Euro 2 Pallets

The Euro 2 pallet is used in a wide range of industries and applications, thanks to its versatility and reliability. Some of the most common uses include:

- Warehousing: Euro 2 pallets are widely used in warehouses for the storage and organization of goods. Their standardized dimensions make them compatible with various storage systems, such as pallet racks and shelving units.

- Transportation: The Euro 2 pallet is commonly used for the transportation of goods, both domestically and internationally. Its robust construction and load capacity make it suitable for a wide range of goods, from consumer products to industrial equipment.

- Retail: Many retailers use Euro 2 pallets for the display and transportation of goods in stores. The pallet’s uniform size and design make it easy to integrate into existing retail systems and processes.

- Manufacturing: In manufacturing facilities, Euro 2 pallets are used for the storage and transportation of raw materials, components, and finished products. Their durability and load capacity make them ideal for handling heavy or bulky items.

- Agriculture: Euro 2 pallets are also used in the agricultural industry for the storage and transportation of produce, such as fruits, vegetables, and grains. The pallet’s design allows for proper airflow and drainage, which is important for maintaining the quality of perishable goods.

8. Comparison with Other Euro Pallet Types

The Euro pallet family includes several different sizes, each designed to meet specific logistical needs. The Euro 2 pallet is just one of these sizes, and it’s important to understand how it compares to other Euro pallet types, such as the Euro 1, Euro 3, and Euro 6 pallets.

- Euro 1 Pallet: The Euro 1 pallet is the most common type of Euro pallet, with dimensions of 1200mm x 800mm. It is slightly narrower than the Euro 2 pallet, making it suitable for goods that require a more compact footprint. The Euro 1 pallet is widely used in industries such as retail, manufacturing, and logistics.

- Euro 3 Pallet: The Euro 3 pallet has dimensions of 1200mm x 1000mm, making it the same width as the Euro 2 pallet but slightly longer. This size is often used for goods that require more space, such as large appliances or machinery.

- Euro 6 Pallet: The Euro 6 pallet is the largest of the Euro pallet family, with dimensions of 1200mm x 1200mm. It is designed for goods that require a larger footprint, such as bulk items or oversized products.

While each Euro pallet type has its own advantages, the Euro 2 pallet stands out for its balance of size, load capacity, and versatility. Its dimensions make it suitable for a wide range of goods, while its robust construction ensures that it can handle the demands of various industries.

9. Sustainability and Environmental Impact

In today’s world, sustainability is a key consideration for businesses across all industries. The Euro 2 pallet, like other wooden pallets, offers several environmental benefits that make it a sustainable choice for businesses looking to reduce their carbon footprint.

- Renewable Resource: Wood is a renewable resource, meaning that it can be replenished over time through responsible forestry practices. This makes wooden pallets a more sustainable option compared to pallets made from non-renewable materials, such as plastic or metal.

- Recyclability: Wooden Euro 2 pallets can be recycled at the end of their life cycle, reducing the amount of waste that ends up in landfills. Additionally, damaged pallets can often be repaired and reused, further extending their lifespan and reducing the need for new pallets.

- Carbon Sequestration: Wood has the ability to sequester carbon, meaning that it absorbs and stores carbon dioxide from the atmosphere. This helps to reduce the overall carbon footprint of the supply chain and contributes to the fight against climate change.

- Energy Efficiency: The production of wooden pallets requires less energy compared to the production of plastic or metal pallets. This further reduces the environmental impact of wooden pallets and makes them a more sustainable choice.

10. Maintenance and Repair of Euro 2 Pallets

Proper maintenance and repair are essential to ensure the longevity and performance of Euro 2 pallets. Regular inspection and maintenance can help to identify and address any issues before they become major problems, reducing the risk of damage to goods and equipment.

- Inspection: Regular inspection of Euro 2 pallets is important to identify any signs of wear and tear, such as cracked or broken boards, loose nails, or damaged corners. Pallets that show signs of damage should be removed from service and repaired or replaced as needed.

- Cleaning: Keeping Euro 2 pallets clean is important to prevent the buildup of dirt, debris, and contaminants that could affect the quality of goods. Pallets should be cleaned regularly using appropriate methods, such as pressure washing or steam cleaning.

- Repair: Damaged Euro 2 pallets can often be repaired, extending their lifespan and reducing the need for new pallets. Common repairs include replacing broken boards, tightening loose nails, and reinforcing weak corners. It’s important to use high-quality materials and proper techniques when repairing pallets to ensure that they remain safe and reliable.

- Storage: Proper storage of Euro 2 pallets is important to prevent damage and ensure that they remain in good condition. Pallets should be stored in a dry, well-ventilated area, away from direct sunlight and moisture. Stacking pallets properly can also help to prevent damage and make them easier to access when needed.

11. Regulations and Standards

The Euro 2 pallet, like other Euro pallets, is subject to various regulations and standards that ensure its quality, safety, and compatibility with different handling equipment and storage systems. Some of the key regulations and standards include:

- EPAL Standards: The European Pallet Association (EPAL) sets the standards for Euro pallets, including the Euro 2 pallet. These standards cover aspects such as dimensions, construction, materials, and load capacity, ensuring that all Euro pallets meet the same high-quality standards.

- ISPM 15: The International Standards for Phytosanitary Measures (ISPM 15) regulates the international movement of wooden packaging materials, including Euro 2 pallets. This standard requires that wooden pallets be treated to prevent the spread of pests and diseases, typically through heat treatment or fumigation.

- ISO Standards: The International Organization for Standardization (ISO) has established several standards related to pallets, including ISO 6780, which specifies the dimensions and tolerances for flat pallets. These standards help to ensure that pallets are compatible with different handling equipment and storage systems.

- National Regulations: In addition to international standards, Euro 2 pallets may also be subject to national regulations and standards, depending on the country in which they are used. It’s important for businesses to be aware of these regulations and ensure that their pallets comply with all relevant requirements.

12. Cost Analysis: Euro 2 Pallets vs. Other Pallets

When choosing pallets for your business, cost is an important factor to consider. The Euro 2 pallet offers several cost advantages compared to other types of pallets, making it a cost-effective choice for many businesses.

- Initial Cost: The initial cost of a Euro 2 pallet is generally lower than that of plastic or metal pallets, making it a more affordable option for businesses with budget constraints. The use of high-quality wood and efficient manufacturing processes helps to keep costs down while maintaining the pallet’s quality and durability.

- Maintenance and Repair Costs: Wooden Euro 2 pallets are relatively easy and inexpensive to repair, compared to plastic or metal pallets. This can help to reduce long-term maintenance costs and extend the pallet’s lifespan, further enhancing its cost-effectiveness.

- Replacement Costs: The durability of Euro 2 pallets means that they need to be replaced less frequently than other types of pallets, reducing replacement costs over time. Additionally, the ability to recycle and repair wooden pallets can further reduce the need for new pallets, saving businesses money in the long run.

- Transportation Costs: The standardized dimensions of Euro 2 pallets make them easy to stack and transport, reducing transportation costs. Their compatibility with various handling equipment and storage systems also helps to streamline logistics processes, further reducing costs.

13. Future Trends in Pallet Design and Usage

As the logistics and supply chain industry continues to evolve, so too does the design and usage of pallets. Several trends are emerging that are likely to shape the future of pallet design and usage, including:

- Automation: The increasing use of automation in warehouses and distribution centers is driving the need for pallets that are compatible with automated handling equipment, such as robotic palletizers and automated guided vehicles (AGVs). Euro 2 pallets, with their standardized dimensions and robust construction, are well-suited to meet this demand.

- Sustainability: As businesses become more focused on sustainability, there is a growing demand for pallets that are made from renewable materials and can be easily recycled or repaired. Wooden Euro 2 pallets, with their renewable and recyclable properties, are well-positioned to meet this demand.

- Smart Pallets: The integration of technology into pallets, such as RFID tags and sensors, is becoming increasingly common. These “smart pallets” can provide real-time information on the location, condition, and status of goods, improving supply chain visibility and efficiency. While this technology is still in its early stages, it has the potential to revolutionize the way pallets are used in the future.

- Customization: As businesses seek to optimize their supply chains, there is a growing demand for customized pallets that are tailored to specific needs. While Euro 2 pallets are standardized, there is potential for customization in terms of materials, load capacity, and other features to meet the unique requirements of different industries.